Yes, a propane generator can run on natural gas with the appropriate modifications. You must install a tri-fuel conversion kit to the generator to achieve this, or you can simply use the DIY method, which is not recommended but mentioned for learning below.

Understanding Propane and Natural Gas Generators

Propane: Propane is a hydrocarbon gas used for heating, cooking, and powering appliances. It’s stored in tanks as a liquid and converts to gas when released. It’s used in residential heating systems, stoves, water heaters, and vehicles as propane autogas.

Natural Gas: Natural gas, primarily methane, is a fossil fuel used for heating, electricity, and vehicle fuel. It’s often found underground or extracted with oil.

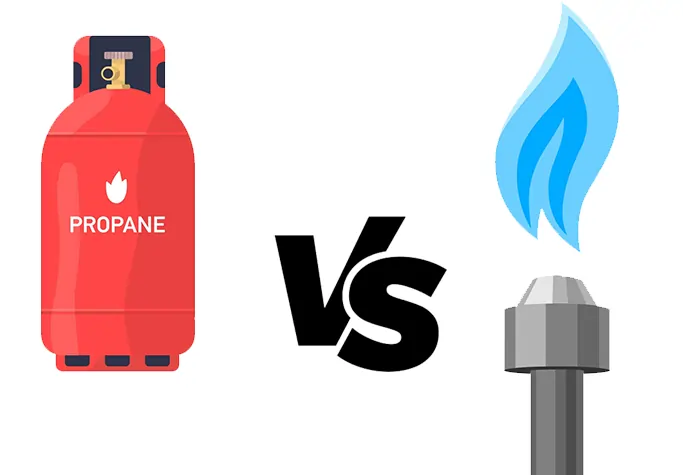

Differences Between Propane and Natural Gas

Certainly, here are the key differences between propane and natural gas:

| Properties | Propane | Natural Gas |

|---|---|---|

| Composition | ✔️Propane is a gas made up of three carbon and eight hydrogen atoms. ✔️It is produced during natural gas processing and crude oil refining. | ✔️Natural gas is predominantly methane (CH4) commonly found in oil deposits or reservoirs. |

| Energy Content | ✔️Propane contains more energy per unit volume than natural gas, producing higher energy output when burned. | |

| Storage and Transportation | ✔️Propane is stored in pressurized tanks as a liquid. When released, it converts to gas. ✔️It’s frequently used in areas without natural gas pipelines. | ✔️Natural gas is transported via pipelines, but CNG and LNG, used for transportation, require specialized handling and storage. |

| Density | ✔️Being denser than air, propane can accumulate in low-lying areas in case of a leak, posing a safety risk. | ✔️Natural gas rises and disperses quickly when released because it is lighter than air. |

| Use Cases | ✔️Propane is a versatile fuel source commonly used in residential and industrial settings for heating homes, cooking, water heating, and powering appliances such as stoves, ovens, and generators. | ✔️Natural gas has a variety of uses, such as generating electricity, heating homes, powering industry, and fueling vehicles. |

| Availability | ✔️Propane is a readily available fuel that can be transported and stored in tanks, making it a viable option for areas without access to natural gas pipelines. | ✔️Natural gas may not be available in remote areas without pipeline access. |

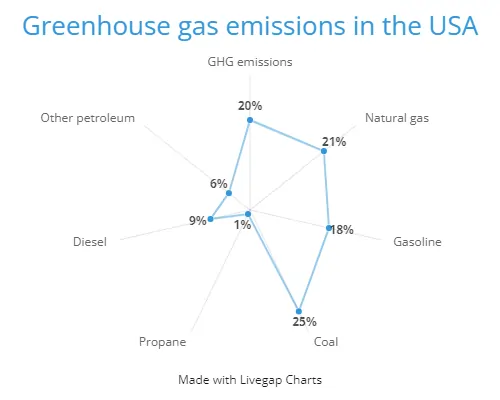

| Environmental Impact | ✔️Propane emits fewer greenhouse gases and pollutants than other fossil fuels, making it a cleaner-burning fuel. | ✔️Natural gas is a cleaner fossil fuel emitting fewer pollutants and greenhouse gases when burned. |

Benefits of Natural Gas

Natural gas is a widely sought-after alternative to propane, primarily due to its multifaceted benefits across various applications.

- Lower Emissions: Natural gas combustion produces fewer emissions and pollutants than propane, coal, or oil, making it a cleaner option for reducing greenhouse gas emissions and improving air quality. This includes reduced particulate matter and sulfur dioxide emissions, which leads to cleaner air and better respiratory health.

- Lower Cost: Natural gas tends to be more cost-effective than propane in many regions due to its abundant supply and efficient extraction processes. This can lead to cost savings for residential, commercial, and industrial users.

- Pipeli ne Infrastructure: In areas with natural gas pipelines, accessing natural gas eliminates the need for propane storage and regular deliveries since it can be directly accessed through the existing pipeline network.

- Continuous Supply: Natural gas is supplied through pipelines, ensuring a constant and reliable fuel source.

- Higher Energy Density: Natural gas contains more energy per unit volume than propane, allowing for greater energy output with less fuel.

- Electricity Generation: Natural gas is often used for generating electricity due to its efficiency and lower emissions than other fossil fuels. It can quickly respond to changes in electricity demand, making it suitable for balancing renewable energy sources such as solar and wind power.

- Industrial Processes: Natural gas is an essential fuel for many industrial processes, such as manufacturing, refining, and chemical production, due to its high energy content and controlled combustion properties.

- Natural gas can be a cleaner alternative to gasoline and diesel for vehicles in Compressed Natural Gas (CNG) and Liquefied Natural Gas (LNG), reducing emissions and dependence on oil.

- Domestic Production: Several nations possess large reserves of natural gas, providing a means to enhance energy security by decreasing dependency on imported oil.

- Transitional Fuel: Although not a complete solution to climate change, natural gas can act as a transitional energy source until renewable energy sources like solar, wind, and hydrogen become more widely adopted.

Safety Precautions for Converting Propane Generators to Natural Gas

- When converting a propane generator to natural gas, prioritize professional guidance and comply with local regulations and codes for safety.

- Ensure equipment compatibility, install proper gas supply line with pressure regulation, shutoff valves, and leak detection systems, and provide ventilation and exhaust to prevent carbon monoxide buildup.

- Following the manufacturer’s guidelines when modifying the ignition and wiring is important. Only use approved conversion kits and components.

- Maintaining safety is crucial throughout the process. Therefore it is important to consult with experienced professionals.

Modifying Propane Generators for Natural Gas

Two primary methods for converting propane generators to run on natural gas are using a designed “conversion kit” or modifying the generator.

These kits include specialized regulators, nozzles, and valves for optimal natural gas usage. Professional installation is recommended to ensure proper gas pressure and ignition system adjustment, providing greater safety and convenience.

The DIY method, while flexible, requires a comprehensive understanding of natural gas and generator mechanism.

Precise adjustments to gas pressure and air-fuel mixture are necessary for safe and efficient operation. If done inaccurately, DIY conversions carry higher risks, leading to gas leaks, poor performance, or hazardous situations.

When choosing a gas installation method, safety should be the top priority. It is recommended to seek professional guidance and conduct thorough testing for both options. Additionally, consider the technical proficiency required versus the peace of mind of professional installation using a conversion kit.

Tri Fuel Conversion Kits Installation Process:

Before installing a tri-fuel conversion kit on your generator:

- Make sure that the generator does not contain gasoline.

- Assemble the gas kit and ensure that all connectors are properly sealed.

- Uncover the generator and remove the breather tube or pipes from the air filter.

- Remove the whole air filter box, then remove the gasket from the engine chiller connection.

- After removing the gasket, install the conversion kit connector on the Shiller, and reconnect the air box.

- Place the tri-fuel kit correctly in the generator and connect the natural gas line to the kit.

- Adjust the pressure from the conversion kit and start the generator.

DIY Modification With Generator

When using the DIY method, connect the air box to the gas line via a hole to inhale natural gas instead of air or propane. Watch the video for more details.

User Experience and Recommendations

Users who have converted their generators to natural gas generally report satisfactory performance. However, it is recommended to consult professionals and consider individual generator specifications before switching.

Factors to Consider Before Converting

Before converting a propane generator to natural gas, consider these key factors:

- Generator Compatibility: Check with the manufacturer or a technician to confirm that your propane generator is compatible with natural gas conversion.

- Safety: Safety should be a top priority when converting a generator to work with flammable gases and altering combustion systems. If you lack expertise, seek professional help to avoid risks like gas leaks, improper combustion, and fire hazards.

- Regulations and Codes: It is important to be familiar with local building codes, regulations, and permits when installing or converting to natural gas to ensure compliance with safety standards and legality.

- Professional Expertise: Consulting with a qualified professional or technician experienced in gas conversions is highly recommended. They can guide you through potential challenges and ensure proper adjustments.

- Conversion Kits: It is recommended to use a conversion kit specifically designed for your generator model, as these kits come equipped with necessary components for safe and efficient natural gas use, including regulators and nozzles.

- Components Sourcing: If you plan to do it yourself, make sure you can find high-quality components compatible with natural gas. These components may include regulators, nozzles, valves, and necessary adaptors.

- Gas Supply: Ensure your location has a dependable natural gas supply with sufficient gas pressure and flow rates for optimal generator performance.

- Gas Pressure Regulation: Natural gas and propane operate at different pressure levels. Ensuring proper gas pressure regulation is crucial for safe and efficient combustion.

- Consulting a professional is crucial to ensure natural gas and propane’s safe and efficient combustion, as they operate at different pressure levels.

- Ignition System: It is important to understand the technical requirements and necessary modifications for a successful conversion to natural gas, including adjustments to the ignition system.

- Performance and Efficiency: Evaluate how the conversion would affect the generator’s performance, efficiency, power output, fuel consumption, and runtime.

- Warranty: Check if converting the generator will void any existing warranties, as some manufacturers may not cover damage or issues resulting from conversions.

- Costs: Calculate the costs of converting to natural gas, including components, professional assistance, permits, and adjustments for optimal generator performance. Thorough testing and inspection are necessary post-conversion to address leaks or improper combustion issues.

Final Conclusion

It’s best to hire a professional to convert a propane generator to run on natural gas for safety and effectiveness. Take precautions and seek expert help.

Properly adjusting gas pressure, ignition systems, and leak-free connections requires expertise for efficient performance and safety. The tri-fuel conversion kit is a highly recommended option.

Experts designed these seamless transition kits for reliable and convenient use. Trusting professionals and a tri-fuel conversion kit ensure a successful switch to natural gas, with optimal efficiency and safety standards.

FAQs

can a propane generator run on natural gas?

Yes, it is possible to run, but you need a few modifications in your generator.

Are natural gas and propane generators the same?

No, natural gas and propane generators use different fuels.

Can natural gas be used in a generator?

Yes, natural gas can power generators for cleaner electricity, but setup costs, fuel supply, and safety precautions are important factors to consider.

Can I run a Honda generator on natural gas?

Yes, with conversion kits, a Honda generator can run on natural gas. But check for approval, ensure safety, consider expertise, and be aware of costs.

Is it cheaper to run a generator on propane or natural gas?

Natural gas is generally cheaper than propane for running a generator.

![Can a Propane Generator Run on Natural Gas? [Easy Solution]](https://whatgenerators.com/wp-content/uploads/thumbs_dir/smallest-portable-generatotrs-feature-image-qb2t7kr2icnzkc394vt2piry1fbiegpn0hvvi2gd30.webp)

![Can a Propane Generator Run on Natural Gas? [Easy Solution]](https://whatgenerators.com/wp-content/uploads/thumbs_dir/7-Best-Portable-Generators-With-a-50-Amp-Plug-feature-image-qbabanzzq8udm2rc48qneflyp5g1l5pfhbph3zxjjw.webp)