A Pull cord starter (recoil starter) plays a crucial role in generator starting, but it is also the most problematic part that portable generator users face. This is why I decided to write a comprehensive guide to help you troubleshoot common issues like a locked or hard-to-pull cord, broken rope, and replacement of pull cord.

You will also learn emergency DIY repair steps. With this guide, you will be able to handle any generator pull cord challenges.

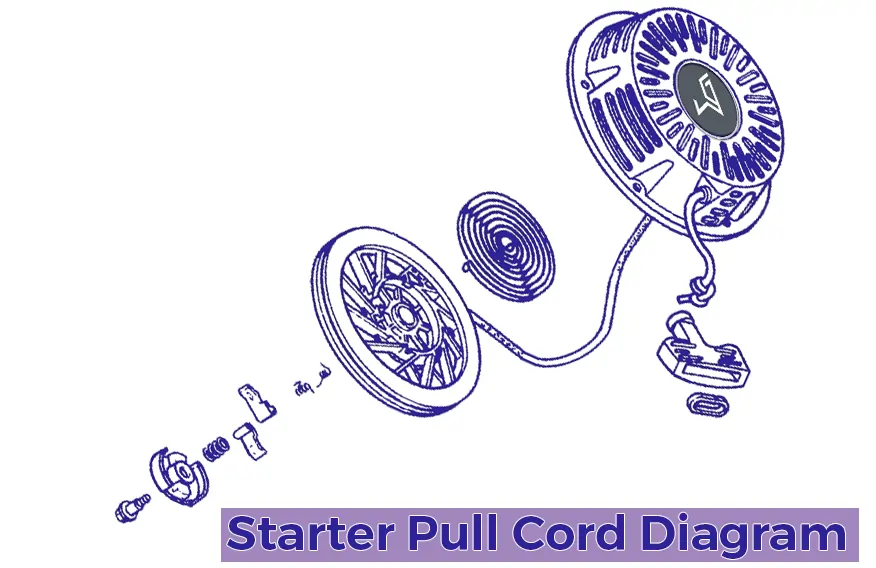

The Basics of Pull Cord Mechanisms

The pull cord mechanism is a simple and essential part of certain machines, such as generators and lawnmowers, used to start their engines manually. It typically consists of a cord wound around a pulley and connected to the engine’s crankshaft.

When you pull the cord, it rotates the engine’s crankshaft, initiating the combustion process and allowing the engine to start.

This manual starting method is commonly employed in portable generators and other small engine-powered devices, providing a straightforward and reliable way to kickstart the engine without the need for an electric starter.

4 Reasons If Your Generator’s Pull Cord Is Locked & Hard To Pull

When a generator’s Pull Cord is locked five main reasons could be responsible for that. I will cover them all but let’s try the most common one first.

Recoil Starter Assembly

The recoil starter assembly is the most common problem in pull cord locks. To check whether it is faulty or not we need to just remove the whole starter assembly from the generator and pull it without the generator attached, easy to pull means “starter assembly is OK” and lock means “faulty starter assembly”.

What if Your Starter Assembly is Damaged?

A faulty recoil starter can be fixed by replacing the damaged parts with a new one or just doing some adjustments to the old parts. First, you need to disassemble the assembly and keep each carefully.

There are a few parts that can cause problems in the cord. Find the problematic part and replace it with a new one.

- Check “Starter Ratchet/Clutches” If found faulty replace it with a new one.

- Check the “friction spring” if found faulty replace it with a new one.

- Check the “Ratchet Guide” Cleaning and replacing is the solution.

- Check the “Recoil Starter Reel” a broken reel needs to be replaced.

- You also need to check the “Recoil Spring”. Sometimes its edges become straight and do not acquire a grip to start. You can use a plier to make it work again or you can simply replace it with a new one.

How To Replace The Damage Rope Of Recoil Starter?

The rope replacement of the rope of recoil starter is an easy task. You can do it by yourself with the help of a few tools.

Required Tools: New rope, Screw Driver.

- Remove the starter assembly from the generator, and don’t dismantle any other part.

- Just rotate the spring anti-clockwise as much as you can and adjust the holes of Polly and assembly cover straight to each other.

- Now you must untie the rope from the inside it is straightforward.

- After that insert the new rope from the cover to Polly from the straight hole and tie it.

- Place the starter assemble back on the generator as it was.

Video for Rope replacement:

How To Replace Damage Spring of Pull Cord?

If the spring inside the pull cord is damaged or broken you need to check the broken point. A spring that is broken from either the middle or pole doesn’t need to be replaced with a new one. This type of damage can be fixed easily. Just bend the spring on the left side as mentioned in the images and you are ready to go.

If the spring is broken at any part that shortens its size after repair, then replacing it with a new one is essential.

Follow the following steps to replace the spring with ease.

- Make sure that both ends of the spring are bent towards your left side making a V shape.

- The Generator Is Hydro Lock Or Seized Up Piston

Hydro lock happens in 2-stroke and 4-stroke engines. This problem occurs when some liquid comes between the cylinder and the piston. And because it is impossible to compress the liquid the piston is unable to get to the top

This problem can be identified but removing the spark plug and just giving a kick to the starter it kicks it means that your generator is hydro-locked.

When a recoil starter is used it pushes the piston to the top of the cylinder, and because there is liquid between them it makes the starting process hard and makes the pull cord stuck.

Possible Causes:

- This can be caused by tipping over the generator in the wrong way which makes engine oil seep to the cylinder.

- The needle seed inside the carburetor allows fuel to cylinder.

Solution:

- Remove the spark plug with the help of the spark plug key.

- Turn it upside down and drain the liquid from it.

- Pull the recoil starter while the spark plug is removed (keep yourself away from the spark plug hole).

- Switch off the generator.

- Put the spark plug back.

- Start the generator by using a pull cord.

This may produce some smoke but that is normal and will clear the back on.

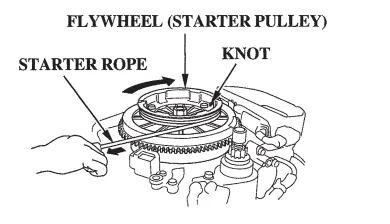

Cracked Flywheel

The Flywheel connects the starter assembly to the engine and makes the engine move while you kick the starter. This is a rare cause of stuck pull cords but this can also be a cause of this issue.

To check the flywheel you need to dismantle the starter assembly from the generator and check it. If it is cracked or broken replacement is necessary.

Pull Cord Emergency DIY Starting Trick For Generators

If you find yourself in a situation where your generator’s pull cord gets faulty and you are unable to get any professional help. This is possible during outdoor activities, camping trips, or in remote locations where access to mechanics is limited.

In this case, follow the below DIY trick to start the generator.

Step 1: Detach the Pull Cord

Carefully remove the pull cord from its housing on the generator. This may require unscrewing the bolts.

Step 2: Free the Rope

Once the pull cord is detached, unravel the rope from its pulley mechanism. Ensure the rope is completely free and not tangled.

Step 3: Locate the Engine Head

Find the engine head of your generator. This is the part of the engine where the pull cord was previously attached.

Step 4: Wind the Rope To The Engine Head

Take the free end of the rope give a tie on and make it stuck in the hook of the engine head.

Begin winding it around the engine head. Make several loops around the engine head to ensure a secure grip. The picture is given for easy understanding.

Step 5: Test and Pull

Once the rope is wound around the engine head, grasp it firmly with your hand.

Give the rope a firm pull to initiate the starting process. Repeat the pulling process as needed until the generator engine starts.